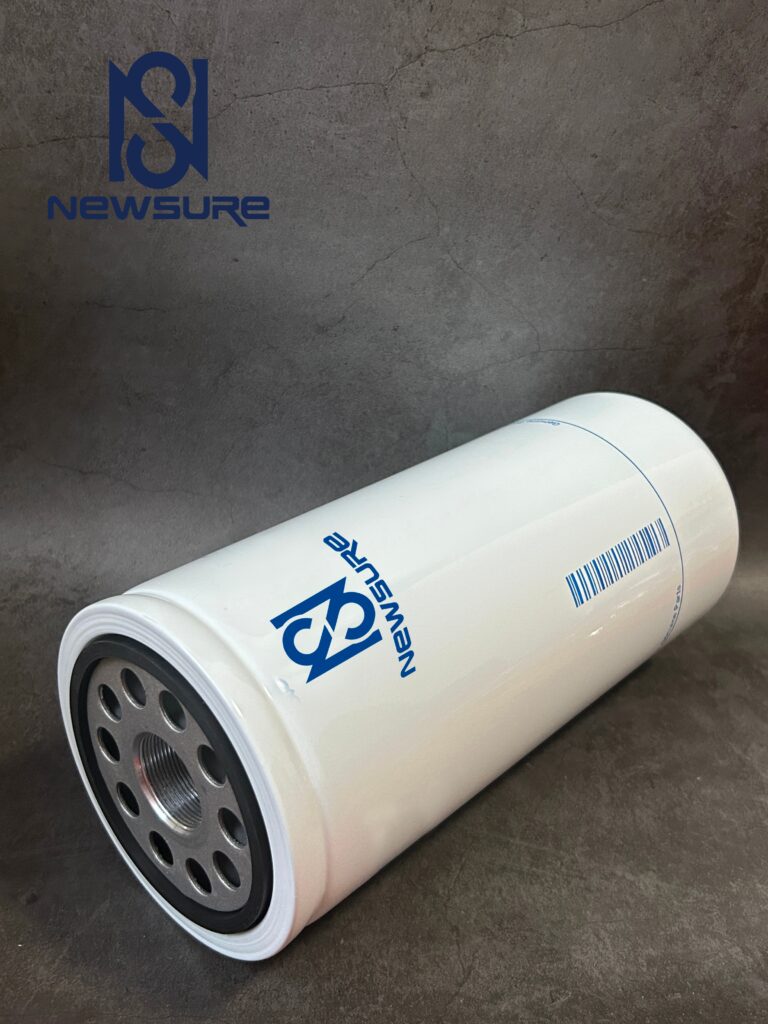

NEWSURE OIL FILTER

Customer Success, Shared Future

NEWSURE specializes in high-quality truck oil filters designed to meet the needs of importers and distributors. Our filters ensure optimal engine performance and long-lasting reliability by providing superior oil cleanliness and boosting engine efficiency. Built for durability, they are ideal for companies looking for customizable, high-performance solutions. Trust NEWSURE to support your business with filters that deliver consistent results and help maintain smooth operations.

Contact us today for tailored solutions that meet your specific requirements.

Your Reliable Partner for High-Quality Truck OIL Filters

When it comes to ensuring optimal engine performance, reliability, and long-lasting efficiency, high-quality truck oil filters are essential. At NEWSURE, we specialize in manufacturing premium truck oil filters that deliver superior filtration and enhanced engine protection, making them the ideal choice for heavy-duty applications.

Our commitment to quality extends to providing customized solutions tailored to your specific needs. With a range of designs and configurations, we focus on delivering products that help maintain smooth operations and reduce downtime for your business.

Choose NEWSURE for oil filters you can rely on—engineered for performance, precision, and durability. Contact us today to discuss how our filters can support your business and meet your operational demands.

HOT SALE OEM-2997305

HOT SALE OEM-320/04133

HOT SALE OEM-4324909

HOT SALE OEM-4587260

HOT SALE OEM-22223804

HOT SALE OEM-82983474

Tailor-Made Truck Oil Filters for Your Unique Business Needs

1. Customized Filter Solutions:

2. Diverse Product Range:

3. Optimized Performance for Longevity:

4. Quality Assurance You Can Trust:

5. Precision Manufacturing Expertise:

6. Partner with NEWSURE for Success:

More Than Just a Truck Oil Filter Manufacturer

1. Tailored Oil Filtration Solutions

2. Personalized Customer Support

3. Flexible Order Quantities

4. Technical Expertise You Can Count On

Why Choose NEWSURE for Your Truck Filter Needs?

Industry Expertise:

Comprehensive Product Range:

Customizable Options:

Consistent Quality:

Can NEWSURE Oil Filters Be Customized to Meet Specific Requirements?

What Is the Typical Lifespan of NEWSURE Oil Filters in Different Applications?

Do You Offer Warranties or Guarantees on the Performance and Durability of NEWSURE Oil Filters?

What Is the Lead Time for Ordering Custom NEWSURE Oil Filters?

What Is the Minimum Order Quantity for NEWSURE Oil Filters?

FAQs About NEWSURE OIL Filters

What is the filtration accuracy of the truck oil filter?

1. Filtration Accuracy Range: Truck oil filters typically have a filtration accuracy range of 10 to 30 microns. Most filters are designed to capture particles as small as 10 microns, effectively removing impurities in the oil and protecting the engine from wear.

2. Filter Material and Design: The accuracy of the filter is also influenced by the filter material (e.g., paper, synthetic fibers) and design. High-quality filters can capture smaller particles more efficiently while maintaining adequate oil flow.

3. Applicability and Brand Differences: Different truck oil filters, depending on the brand and vehicle model, may have varying filtration accuracy. Filters are often optimized for the specific engine type and operating conditions, so it’s important to check the manufacturer’s technical specifications to ensure compatibility with the truck’s engine.

84228488

84171722

How durable and long-lasting is the filter?

The durability and lifespan of truck filters depend on the type and usage conditions:

1. Oil Filters: Typically last 5,000-10,000 miles but may vary based on engine type and oil quality.

2. Fuel Filters: Designed to last 10,000-25,000 miles, depending on fuel quality and operating conditions.

3. Air Filters: Last 15,000-30,000 miles in normal conditions; high-dust environments may require more frequent replacement.

4. Hydraulic Filters: Lifespan varies with system usage, typically around 1,000-2,000 operating hours.

Proper maintenance and adherence to manufacturer guidelines ensure filters deliver reliable performance and extend engine life.

Can the filter withstand high temperature or pressure environments? What are the specific temperature and pressure ranges?

A4731800809

A4731800809

What materials are used for the truck filter media?

Truck filter media materials include:

1.Cellulose (Paper): Cost-effective, good for larger particles.

2.Synthetic: Durable, high efficiency for fine particles, long lifespan.

Glass Fiber: Ultra-fine filtration, heat and pressure resistant.

3.Blended Media: Combines 1.cellulose and synthetic, balances cost and performance.

4.Activated Carbon: Absorbs odors and gases, improves air quality.

5.Metal Mesh: Provides structural stability under high pressure.

The choice depends on filtration efficiency, durability, and operating conditions.

What quality control processes are in place during production?

Quality control processes during production typically include the following steps:

1. Raw Material Inspection

– Testing the quality of filter media, adhesives, and other components for compliance with specifications.

2. In-Process Quality Checks

– Monitoring pleating, sealing, and assembly to ensure uniformity.

– Real-time inspections for defects like uneven pleats or poor bonding.

3. Performance Testing

– Filtration efficiency tests (particle capture).

– Pressure drop and flow rate verification.

– Durability testing under simulated operating conditions.

4. Dimensional Inspection

– Measuring size, shape, and fitting accuracy to match design requirements.

5. Leakage Testing

– Ensuring no air, oil, or fuel bypasses the filter media.

6. Final Product Inspection

– Visual checks for external defects and packaging quality.

– Batch sampling for performance validation.

7. Certification and Documentation

– Providing testing reports and certificates (e.g., ISO 9001, IATF 16949).

These steps ensure filters meet performance and safety standards before shipment.

What are your packaging standards to ensure the filters are protected during shipping?

Packaging standards for truck filters typically include:

1. Individual Packaging:

– Filters are placed in sturdy, corrugated boxes with protective inserts to prevent movement and damage.

– Moisture-proof or anti-static wrapping is used for added protection.

2. Carton Packaging:

– Individual boxes are grouped into larger cartons, secured with padding to absorb shocks during transit.

– Cartons are labeled with product details, quantity, and handling instructions.

3. Palletization:

– Cartons are stacked on durable pallets, shrink-wrapped or strapped to prevent shifting.

– Pallet height and weight are optimized for stability and ease of handling.

4. Custom Packaging (Optional):

– Branding or specific packaging requirements can be accommodated.

These measures minimize risk of damage and ensure filters arrive in good condition.

let's talk about your filter needs

Do you offer EXW,FOB, CIF or DDP shipping terms?

1.EXW (Ex-Works)

2.FOB (Free on Board)

3.CIF (Cost, Insurance, and Freight)

4.DDP (Delivered Duty Paid)

5.Flexibility and Recommendations

Do you have experience in exporting to our country and are you familiar with the import procedures and documents?

Commercial Invoice:

Packing List:

Bill of Lading (BOL):

Certificate of Origin (COO):

Customs Declaration:

NEWSURE exports truck filters to countries like the USA, Canada, Malaysia, and Germany, ensuring compliance with local standards (e.g., EPA, ECE R49). Experienced in handling import procedures and documents, we deliver reliable, high-quality filters tailored to diverse markets, meeting global customers’ needs with smooth customs clearance and efficient delivery.

Let's work together

Let’s work together to drive your business forward! At NEWSURE, From custom designs to certified quality, our products are built to support your success.

Your success is our mission—let’s start today!